Why Choose Us

In the field of optical modules, we stand out with our outstanding overall strength, becoming a trusted partner for our customers.

Home / Why GearLink

The driving force behind technological innovation

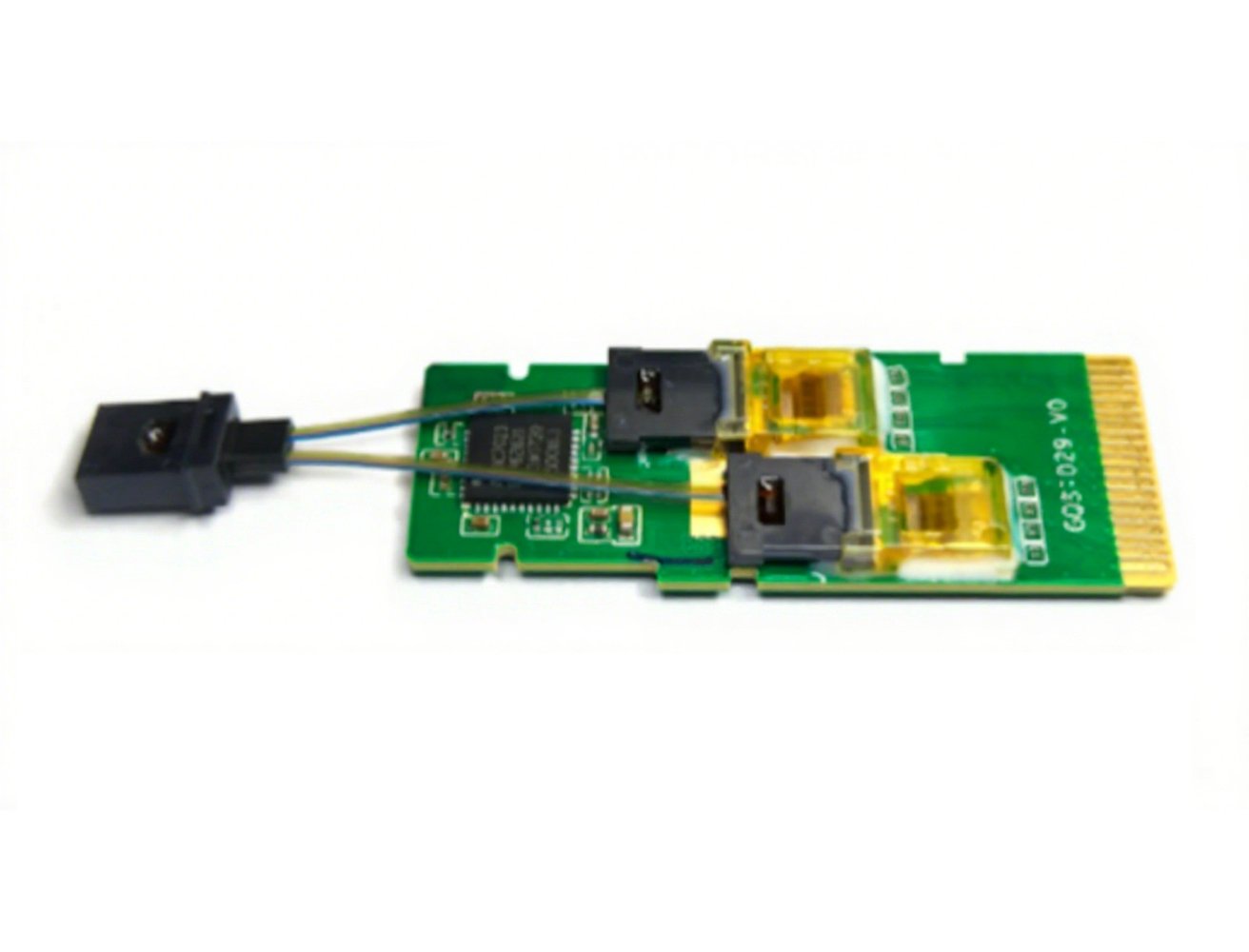

Core Process Advantage: High-Density Optical/Electrical DB-WB Technology

Wuhan Geling Technology boasts a seasoned R&D team specializing in high-density optical/electrical DB-WB (Die Bonding–Wire Bonding) processes, with over 50% of engineers having more than 20 years of experience. Our proprietary DB-WB technology enables multi-chip high-density integration, enhancing signal integrity while reducing power consumption and costs. The incorporation of metal shielding layers significantly improves electromagnetic interference resistance, outperforming similar products by 30%. This technology is applicable to 400G/800G and higher-speed optical communication products, ensuring high performance and reliability.

Proprietary Multi-Channel Laser Coupling Technology

Our self-developed multi-channel laser coupling technology supports 400G/800G/1.6T high-speed optical modules, encompassing various coupling schemes such as VCSEL+MLA, DFB/EML+FA, and SiPh waveguides. Key features include coupling efficiency exceeding 85%, insertion loss below 1 dB, channel power variation within ±0.5 dB, alignment error under 0.5 μm, and exceptional stability under high-temperature and high-humidity conditions. With an automated alignment rate of over 90% and a yield rate exceeding 95%, this technology is well-suited for large-scale production, ensuring consistent performance and quality.

Independently Developed Parallel Automated Testing Technology

Our proprietary parallel automated testing technology for optical modules allows simultaneous multi-channel testing of multiple modules, significantly enhancing testing efficiency and consistency for 400G/800G/1.6T modules. Core components include parallel bit error rate testing, optical power/spectrum analysis, eye diagram testing, temperature aging testing, and automated test software, supporting modulation formats like PAM4 and NRZ. Future expansions may include 32-channel testing capabilities, integration of AI-driven data analysis, and remote testing functionalities, paving the way for fully automated optical module production lines.

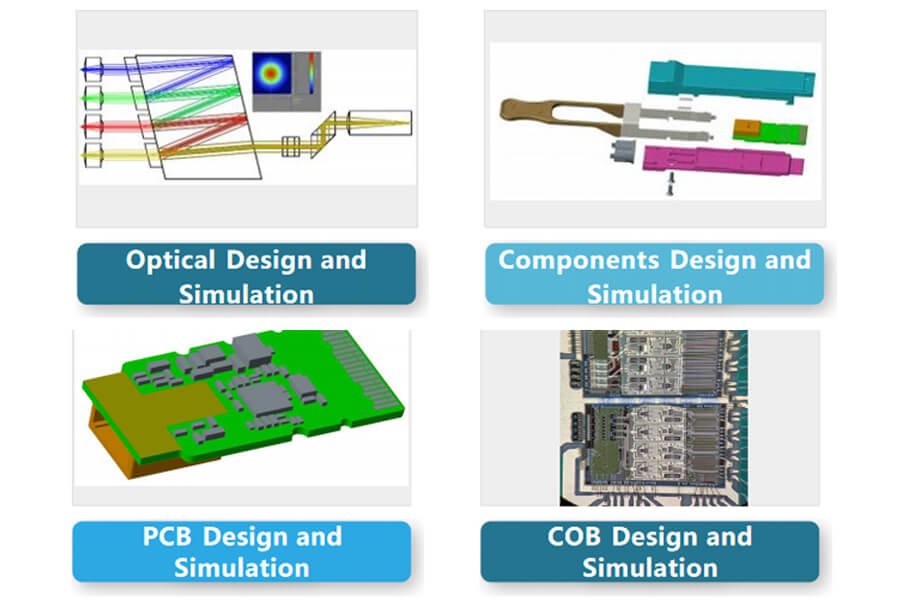

Optoelectronic Design and Device-Level Simulation

Utilization of internationally leading EDA tools for designing low-power, high-bandwidth, and highly reliable optical modules.

Die Attach Process and Equipment

Sub-micron precision die attach processes ensure high reliability and consistency in optical modules.

Wire Bonding Process and Equipment

High-precision wire bonding guarantees stable high-speed signal transmission and long-term reliability.

Automated Optical Path Coupling Process and Equipment

Sub-micron level optical path coupling ensures low insertion loss and high consistency in optical modules.

Design Verification Process and Equipment

Comprehensive verification systems ensure stable performance and military-grade quality of optical modules.

COB Packaging Process and Equipment

Automated precision COB packaging enhances heat dissipation and cost-effectiveness, supporting compact and efficient 800G/400G optical modules.

Optical Engine Assembly and Module Manufacturing

Automated precision assembly in cleanroom environments, coupled with thermal testing, ensures stable performance of 400G/800G modules.

Fully Automated Testing Equipment and Processes

Comprehensive automated testing systems cover electrical, optical, and environmental parameters, ensuring efficient and consistent military-grade optical modules.

Appearance and Physical Inspection

- 360° Automated Optical Inspection (AOI)

- Surface particle control ≤5μm

- Insertion/removal durability ≥500 cycles

Extreme Environmental Reliability Testing

Commercial-grade: 0°C to +70°C, 500 cycles

Temperature change rate: 30°C/min

Damp heat aging: 2000 hours with performance degradation <5%

Protocol Compatibility Testing

Multi-protocol version compatibility verification

Cross-vendor equipment interoperability testing

Dynamic traffic fault tolerance assessment

Transmission Reliability Verification

228-hour high-temperature accelerated aging

Bit error rate testing using PRBS31 patterns

Jitter tolerance testing compliant with OIF-CEI standards

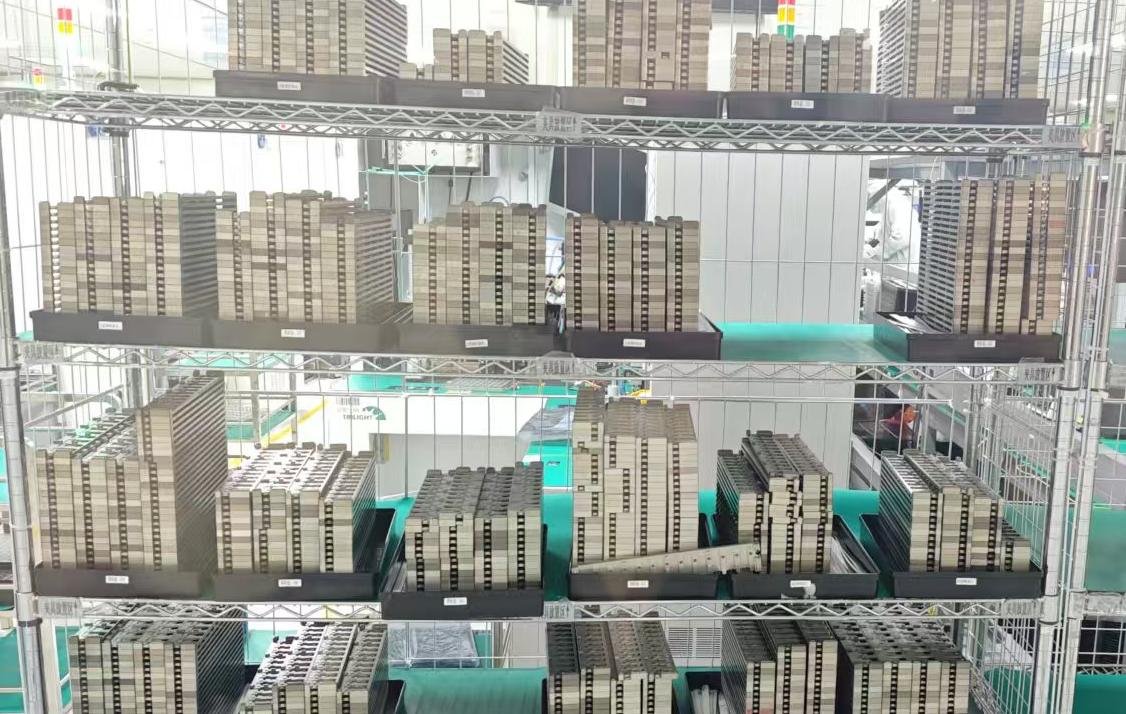

Mass Production Strength

Class 10,000 cleanroom packaging facilities

Annual production capacity of 3 million units, ensuring rapid delivery

Deep Collaboration Models

Joint Design Manufacturing (JDM)

OEM/ODM services

100% Intellectual Property protection

Testing Architecture Design

Physical Layer Verification: Utilization of BERTScope for NRZ/PAM4 signal integrity testing, ensuring interfaces like SFP+/QSFP28/OSFP comply with IEEE 802.3bm/cd standards, with insertion loss <1.5 dB at 28 GHz.

Protocol Layer Verification: Employing Spirent TestCenter to simulate 128-node network topologies, verifying key functions such as FEC correction, Auto-Negotiation, and Link Training, meeting OpenEye Mask specifications.

Application Layer Verification: Constructing real-world traffic models like RoCEv2/FCoE to validate end-to-end latency <200 ns and zero packet loss rate >99.999%.

Warranty Commitment

36-month extended warranty

Next Business Day (NBD) replacement for failures within the first year

Lifetime maintenance at cost price

Global Service Network

24/7 multilingual technical support

Free optical link diagnostic services

Annual preventive maintenance plans

Equipment compatibility upgrade solutions