In the current digital age, the relentless surge of data from Artificial Intelligence (AI), Machine Learning (ML), and cloud services is placing unprecedented strain on existing network infrastructure. Hyperscale data centers, in particular, find themselves at a crucial inflection point, where the 400G capacity that defined the last generation is rapidly becoming insufficient to handle the colossal bandwidth demands of modern computing workloads. This critical need for a new level of density and speed mandates a technological paradigm shift. Consequently, the introduction of 800G transceivers represents not merely an incremental upgrade but a fundamental re-architecture of the optical networking fabric. These advanced optical modules are poised to unlock the necessary throughput, offering network architects and optical module product users a viable path to future-proof their operations against the ever-increasing hunger for bandwidth. The following analysis provides a detailed exploration of this cutting-edge technology, its architecture, essential features, and pivotal applications within the optical module landscape.

The Technological Imperative: Why 800G Optics Demand Attention

The transition from 400G to 800G transceivers is driven by core economic and physical limitations. Simply put, doubling the speed while maintaining the same physical footprint requires ingenuity in signal processing and component miniaturization. The previous generation often relied on 8 channels running at 50 Gbps per lane, but moving to 800G necessitates a breakthrough in how data is encoded and transmitted.

Decoding the Core: PAM4 Signaling and the DSP Engine

The foundation of 800G speed lies in the pervasive adoption and refinement of Pulse Amplitude Modulation-4 (PAM4) technology, working in concert with sophisticated Digital Signal Processing (DSP) chips. Unlike the Non-Return-to-Zero (NRZ) signaling, which uses two levels to represent a single bit (0 or 1), PAM4 utilizes four distinct voltage levels to encode two bits of data (00, 01, 10, or 11) in a single clock cycle. This effective doubling of the bit rate per symbol is crucial for achieving higher bandwidth density without requiring a proportional increase in component cost or physical space.

To achieve 800 Gbps, these new optics commonly leverage 8 lanes of 100 Gbps signaling. However, the PAM4 signaling inherently introduces noise and reduces the signal-to-noise ratio (SNR), especially over longer distances. Consequently, the embedded DSP engine becomes the indispensable backbone of the transceiver. This chip performs advanced equalization, forward error correction (FEC), and signal recovery, compensating for channel impairments. The performance and power consumption of the DSP are, therefore, key determinants of the overall module efficiency and reliability. The evolution of DSP architectures to 7nm and even 5nm fabrication processes has made the high-density deployment of high-speed optical systems both technically feasible and economically attractive for mass deployment.

Density and Efficiency: The New Metrics for Performance

For hyperscale operators, network density and power efficiency are arguably more critical than raw speed alone. The shift to 800G transceivers is designed to address both. By doubling the port capacity while largely retaining the form factors of the 400G generation, data center operators can significantly reduce the number of physical switches and cables required, leading to substantial savings in Capital Expenditure (CapEx) and rack space.

Furthermore, the push for increased power efficiency is paramount. Modern 800G transceivers are engineered to transmit more bits per watt. While higher speeds generally imply higher power draw, continuous innovation in silicon photonics and co-packaged optics (CPO) is driving down the relative power consumption per gigabit. This focus on maximizing throughput while minimizing heat dissipation is vital for maintaining the operational viability and environmental sustainability of massive data center deployments.

Unpacking the Form Factors: QSFP-DD800 vs. OSFP

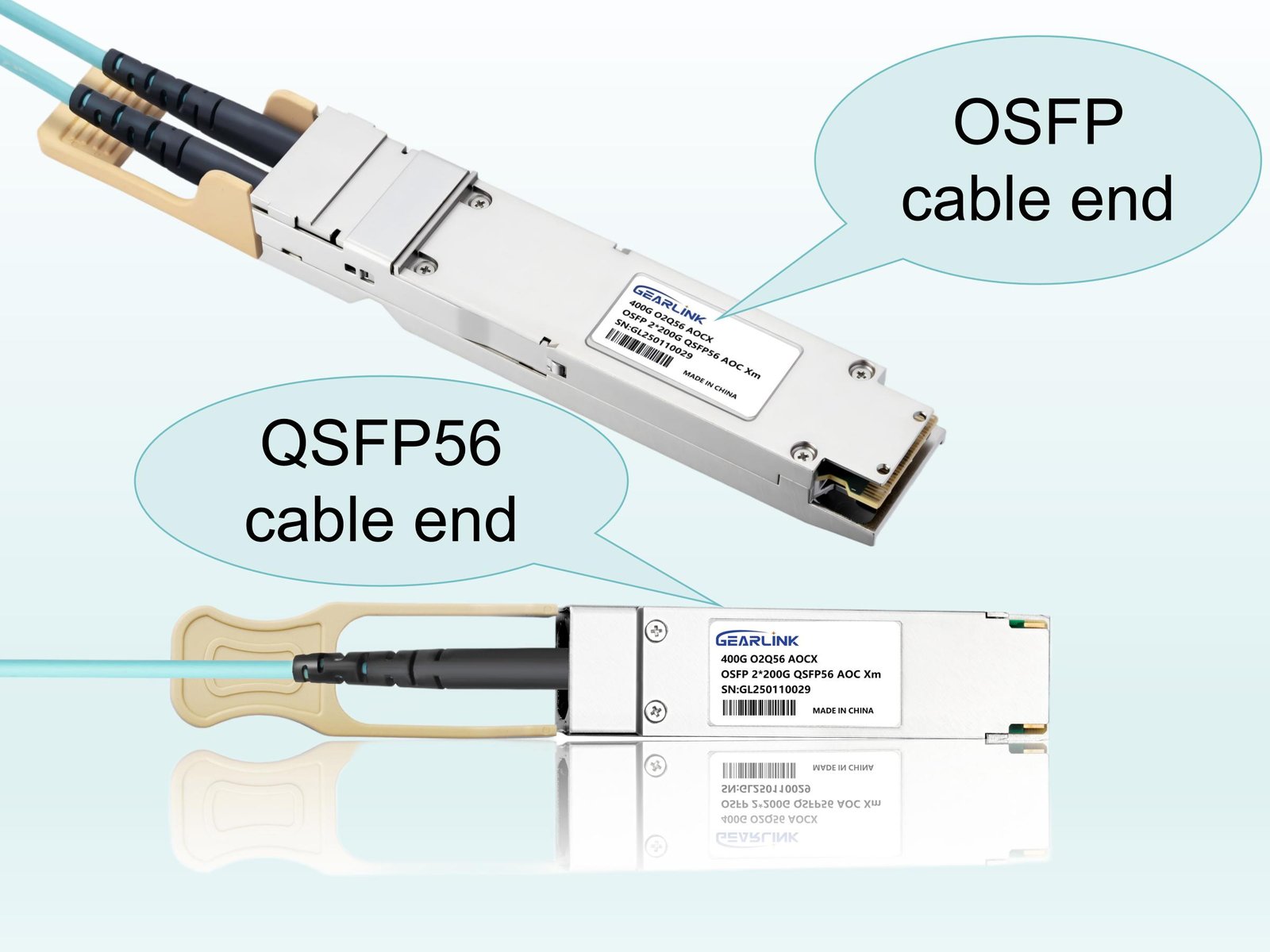

The 800G ecosystem is currently defined by two competing, yet co-existing, small form factor architectures: the Quad Small Form-factor Pluggable Double Density 800 (QSFP-DD800) and the Octal Small Form-factor Pluggable (OSFP). Optical module product users must carefully consider the distinct advantages of each when planning future deployments.

The Evolution of Pluggable Interfaces

The QSFP-DD800 is a direct and logical extension of the widely adopted 400G QSFP-DD standard. It maintains backward compatibility with previous QSFP modules, offering a smooth upgrade path and ease of integration into existing chassis designs. Its core design allows for a high density of ports on a switch faceplate, which is highly desirable for intra-data center spine-leaf architectures. For many enterprises prioritizing density and familiarity, QSFP-DD800 is the preferred choice.

In stark contrast, the OSFP form factor is slightly larger, which was initially designed to accommodate the higher power consumption of the first generation of 800G optics. This larger size allows for improved thermal management and can sometimes house more complex optics or integrated heat sinks. OSFP also has the potential to scale to higher speeds in the future due to its architecture. While its density is slightly lower than QSFP-DD800, its robust thermal performance makes it a strong contender for applications demanding maximum performance stability over extended operational periods. The industry continues to drive standardization, however, the coexistence of both form factors requires flexible switching gear to support the varied deployment needs of the global market.

Applications and Deployment Scenarios in Optical Networks

800GBASE 2 x DR4/DR8 OSFP PAM4 1310nm 500m DOM Dual MPO-12/APC SMF Optical Transceiver Module

Price range: NT$1,699 through NT$1,768

800G OSFP SR8-800GBASE 2 x SR4/SR8 OSFP PAM4 850nm 50m DOM Dual MPO-12/APC MMF InfiniBand NDR Optical Transceiver Module

Price range: NT$539 through NT$808

The true value of 800G transceivers is realized in their capacity to enable entirely new levels of network performance across several critical domains. Focusing on the user of optical module products, these modules solve bandwidth bottlenecks in the most demanding environments.

Hyperscale Data Center Interconnect (DCI)

The most immediate and impactful application is within Hyperscale DCI. DCI links connect geographically dispersed data centers, allowing them to function as a single logical entity. As the volume of east-west traffic (server-to-server communication) explodes, DCI capacity must scale proportionally. 800G transceivers facilitate the aggregation of massive traffic flows onto single, high-capacity coherent links, reducing the complexity of the fiber plant and decreasing operational expenses. Consequently, the ability to transmit more data using the same number of fibers results in significant cost reduction per bit, which is a major benefit for large cloud providers.

High-Performance Computing (HPC) Clusters

Within HPC and AI/ML training clusters, low latency and extremely high bandwidth are not luxuries but fundamental requirements. These clusters rely on tightly coupled interconnects to allow thousands of GPUs and CPUs to exchange data efficiently during complex parallel processing tasks. Here, 800G transceivers are deployed for high-density, low-latency links between processing nodes and distributed memory pools. The technology enables faster data synchronization and checkpointing, directly translating to quicker model training and higher computational throughput. Moreover, the use of Active Optical Cables (AOCs) built around 800G technology allows for high-speed connectivity over short distances within a rack or between adjacent racks, bypassing the need for complex and power-hungry active switching elements for every link.

Future-Proofing the Metro and Access Network

While primarily focused on data centers, the underlying technology of 800G transceivers will inevitably cascade into Metro and Access networks. Service providers are constantly upgrading their infrastructure to support residential and business demand for 10G/25G services. The deployment of 800G backbones provides the foundational capacity needed to aggregate traffic from numerous access points onto a high-speed core. This proactive scaling ensures that the network is ready for future service demands, such as 5G densification and the widespread adoption of bandwidth-intensive Augmented and Virtual Reality (AR/VR) applications. Therefore, for those planning long-term infrastructure investments, adopting 800G technology ensures longevity and scalability.

Navigating the Migration: Challenges and Considerations for Users

The migration to 800G technology, while promising, presents several practical challenges that optical module product users must strategically address. A smooth transition hinges on meticulous planning regarding interoperability, thermal management, and long-term cost of ownership.

Interoperability and Backward Compatibility

A primary concern is ensuring seamless interoperability between new 800G gear and the existing 400G and 100G infrastructure. Thankfully, the QSFP-DD800 form factor inherently supports backward compatibility, often allowing a single switch port to accept modules of different speeds. However, true interoperability requires rigorous testing and adherence to multi-source agreements (MSAs) to ensure that optics from different vendors function reliably together. Users must prioritize vendors, like Optictran, who demonstrate a commitment to standardized compliance and open-source testing methodologies. This due diligence ensures that capital investment is protected and avoids costly vendor lock-in scenarios.

Thermal Management: Keeping the High-Speed Engines Cool

As speeds increase, so does power density, making heat dissipation a significant engineering hurdle. A typical 800G module can draw considerably more power than its 400G predecessor. This higher power draw translates directly into increased heat, which must be efficiently extracted from the switch and the data center environment. Switches designed to support 800G must feature advanced air-flow designs and robust heat sink mechanisms. For the end-user, this means considering not just the transceiver’s performance specifications, but also its maximum power rating and the cooling capabilities of the host equipment. Failure to manage thermal load effectively can lead to performance throttling, reduced module lifespan, and potential network instability. Consequently, optimal thermal management is non-negotiable for maximizing the return on investment in these high-speed systems.

In conclusion, the era of 800G transceivers is fully underway, driven by the insatiable demands of AI and cloud computing. The sophisticated integration of PAM4 and powerful DSPs, coupled with robust form factors like QSFP-DD800 and OSFP, provides a clear pathway to next-generation network architecture. By carefully evaluating the technological shifts, the deployment scenarios, and the inevitable challenges of heat and interoperability, optical module product users can confidently leverage this leap to build the most advanced, dense, and energy-efficient networks the world has ever seen.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between QSFP-DD800 and OSFP for 800G deployment? A: QSFP-DD800 offers higher density and better backward compatibility with previous QSFP generations, making it ideal for large-scale data center core switching. OSFP is physically larger, often allowing for superior thermal management and higher power capacity, which can be advantageous in certain high-heat, high-performance environments.

Q2: Will 800G technology replace 400G immediately? A: No. 800G transceivers will initially be adopted in areas with the most severe bandwidth bottlenecks, primarily hyperscale data centers and major core routers. 400G will remain the economic sweet spot for many medium-to-large enterprise and regional deployments for the foreseeable future, creating a tiered deployment strategy.

Q3: What role does Silicon Photonics play in 800G? A: Silicon Photonics is fundamental to 800G and beyond. By integrating optical components directly onto a silicon chip, it facilitates the high-volume, low-cost manufacturing of complex optical engines. Crucially, it improves power efficiency and allows for the necessary high-density integration required for the 100 Gbps per lane signaling used in 800G transceivers.