The escalating demand for bandwidth, primarily driven by cloud computing, AI, and hyper-scale data centers, has unequivocally pushed the industry toward the 400 Gigabit Ethernet (400G) generation. As network architects and product users navigate this transition, a fundamental concern rises to the forefront: 400G module compatibility. This is not merely a technical specification; it is the linchpin for successful, cost-effective, and future-proof network deployments. Understanding the intricacies of compatibility among different form factors, vendors, and network equipment is paramount for ensuring seamless integration and optimal performance in today’s demanding optical networks.

The Foundation of 400G Compatibility: Standards and Form Factors

The journey into 400G module compatibility begins with a thorough understanding of the underlying industry standards and the various physical form factors adopted by transceivers. These standards ensure interoperability, which is the very definition of compatibility in this context. The IEEE 802.3bs and subsequent specifications laid the groundwork for 400G Ethernet, defining the optical and electrical interfaces.

Initially, the 400G landscape was dominated by several competing module types, which necessitated careful consideration for compatibility. The most prominent are:

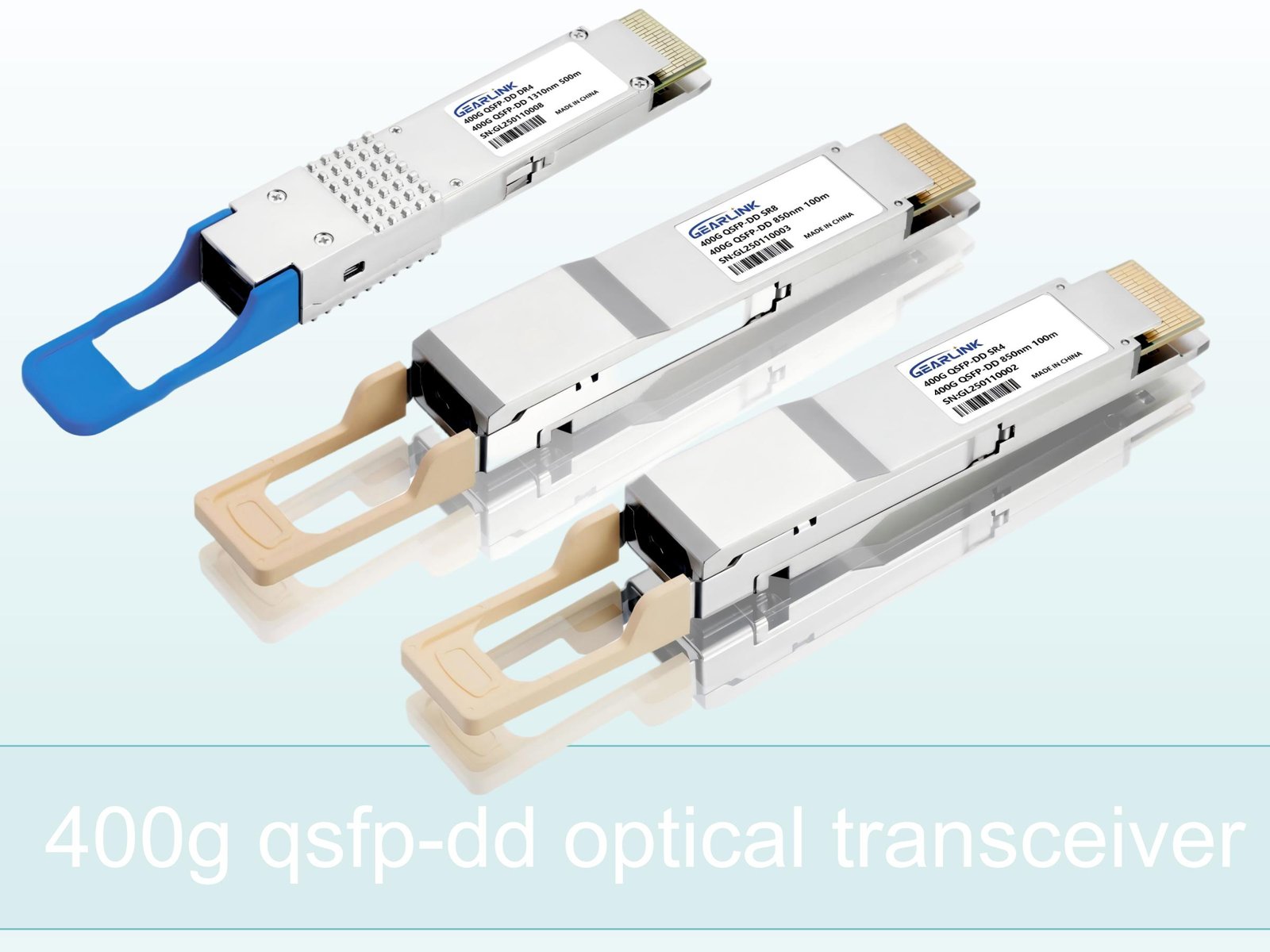

- QSFP-DD (Quad Small Form-factor Pluggable Double Density): This form factor is currently the most widely adopted and is crucial for high-density applications. Its “Double Density” feature allows it to support eight lanes, effectively doubling the port density compared to the previous QSFP standard, making it inherently forward-compatible with existing QSFP infrastructure via adapters. This is a significant factor in facilitating network upgrades.

- OSFP (Octal Small Form-factor Pluggable): Although slightly larger than QSFP-DD, OSFP was designed from the ground up to support high-speed signaling and thermal management, which is critical for 400G power consumption. It integrates a heat sink directly, offering superior thermal performance. While less common in new deployments, its presence still requires consideration for network equipment compatibility.

- CFP8 (C form-factor Pluggable 8): An earlier standard, CFP8 played a role in initial 400G deployments, but its larger size limits its density and scalability in modern data centers. Consequently, the industry has largely converged toward the smaller, denser solutions.

The practical implication of these different form factors is profound. A switch or router line card must physically and electrically support the module type chosen. For instance, if a host device is designed only for QSFP-DD, an OSFP module cannot be physically inserted without an adapter or an entirely different line card, which impacts capital expenditure and operational complexity. Therefore, the physical layer compatibility is the essential first check when designing or upgrading a network.

The Crucial Interplay: Vendor Interoperability and Ecosystem Dynamics

Beyond the physical specifications, 400G module compatibility critically involves the interoperability between different vendors’ products—specifically, the transceiver module and the host switch/router. Network administrators must confirm that a third-party optical module will function reliably with their primary network equipment, such as Cisco, Juniper, or Arista switches.

This verification is complex because transceivers often use an EEPROM (Electrically Erasable Programmable Read-Only Memory) chip to store coding information. The host device reads this code to confirm the module is compatible, a process known as vendor locking or qualification. While many third-party vendors, like Optictran, meticulously code their modules to be 100% compatible and fully functional with major OEM (Original Equipment Manufacturer) switches, this compatibility must be rigorously tested and guaranteed.

- Coding Assurance: Reputable third-party optical module providers ensure their products are coded to emulate the OEM’s specifications perfectly. This allows the host device to recognize the module as legitimate and fully supported, bypassing potential compatibility errors that could lead to link failures or reduced performance.

- Diagnostic Features: A compatible module must also correctly communicate vital diagnostic information via Digital Diagnostics Monitoring (DDM) or Optical Monitoring (OM) features. This includes parameters like transmit power, receive power, temperature, and voltage. If a module fails to report this data accurately, network monitoring and troubleshooting become significantly compromised, which poses an operational risk.

- Protocol Compatibility: Furthermore, the electrical signals must adhere strictly to the established protocols and standards. A compatible module ensures the signal integrity is maintained across the link, adhering to the required FEC (Forward Error Correction) and signaling rates, a necessity for reliable high-speed data transmission.

Thermal and Power Compatibility: Often Overlooked but Critical

400GBASE-SR4 OSFP 850nm 50m DOM MPO-12/APC MMF Optical Transceiver Module

Price range: NT$499 through NT$898

In the domain of 400G module compatibility, the thermal and power aspects are often underestimated. As data rates increase, power consumption inevitably rises, generating more heat. A 400G module can consume significantly more power than its 100G predecessor.

The host device (switch or router) must be engineered to:

- Supply Adequate Power: The line card and backplane must deliver the necessary power within the module’s operating specifications. A mismatch in power requirements can lead to module instability or failure.

- Dissipate Generated Heat: Effective thermal management is paramount. The cooling system of the switch, in conjunction with the thermal design of the module (e.g., integrated heatsink in OSFP or optimized airflow with QSFP-DD), must ensure the transceiver operates within its specified temperature range. Operating outside this range drastically reduces the module’s lifespan and can lead to immediate performance degradation or thermal shutdown. Incompatible thermal designs are a major source of intermittent link failures in high-density 400G deployments.

Therefore, when choosing 400G modules, network professionals must consider the thermal envelope of their existing or planned network equipment. A compatible module must not only function electrically but also integrate smoothly into the switch’s cooling architecture without causing overheating issues in adjacent ports.

Practical Strategies for Ensuring 400G Module Compatibility

For optical module product users, a proactive approach is necessary to ensure successful deployment.

- Prioritize Verified Testing: Always procure modules from vendors that provide comprehensive, real-world testing in the actual host equipment. A compatibility matrix or detailed test reports validating performance across various operating temperatures and different vendor platforms should be non-negotiable.

- Standardization is Key: Wherever possible, standardize on a single, dominant form factor, such as QSFP-DD, to simplify inventory management and reduce complexity. This also maximizes the pool of compatible vendors and components.

- Future-Proofing through Compatibility: Choosing a form factor like QSFP-DD, which offers a clear path for upgrades to 800G and beyond (QSFP-DD800), inherently builds compatibility into the network’s future. This careful selection mitigates the risk of costly full equipment replacements down the line.

- Understand Fiber Compatibility: Compatibility also extends to the physical media. Ensure the 400G module’s specified reach (e.g., DR4, FR4, LR4) is appropriate for the link distance and that the existing fiber plant (e.g., SMF vs. MMF) is compatible with the module’s optical requirements. Using the correct patch cables and connectors is the final, essential step in achieving full link compatibility.

Conclusion

The successful migration to 400G networks hinges on a deep and practical understanding of 400G module compatibility. This multi-faceted concept encompasses physical form factors, adherence to industry standards, rigorous vendor interoperability testing, and critical thermal and power management. By proactively addressing these compatibility challenges, optical module users can guarantee the reliability, efficiency, and scalability of their high-speed data center and telecom networks. Ensuring true compatibility is not just about avoiding immediate failures; it is about strategically laying the foundation for the next generation of digital infrastructure. Optictran remains committed to providing fully compatible, rigorously tested 400G solutions that meet the complex demands of modern optical networks.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between QSFP-DD and OSFP in terms of compatibility? A: QSFP-DD offers higher density and backward compatibility with existing QSFP form factors via adapters, making it easier to integrate into current infrastructures. OSFP is slightly larger, providing better thermal management but requiring new line cards and lacking direct backward compatibility with standard QSFP ports.

Q2: Does using third-party 400G modules void the switch manufacturer’s warranty? A: Reputable third-party vendors provide modules guaranteed to be 100% compatible. While some OEMs may suggest using only their own modules, legal precedence and industry practice support the use of qualified third-party optics. Always choose a vendor, like Optictran, that provides coding and testing assurance to minimize risk.

Q3: How important is FEC (Forward Error Correction) in 400G compatibility? A: FEC is critical. 400G transmission rates rely on FEC to correct errors introduced by higher-speed signaling. A compatible module must correctly implement and communicate the required FEC scheme to the host device to ensure the link operates reliably and meets the required Bit Error Rate (BER) performance.