Managing high-density data centers requires a delicate balance between performance and budget. For short-range connections, a direct attach cable (DAC) is often the most efficient solution. However, procurement teams often struggle with compatibility issues and hidden latency costs. You need to ensure your infrastructure supports high-speed data transfer without unnecessary power consumption. This guide evaluates how to select the ideal cabling to optimize your server-to-switch links. We will focus on reliability, cost-effectiveness, and technical standards for modern networking environments.

What is a Direct Attach Cable and Why Use It?

A direct attach cable is a fixed assembly used to connect network switches to controllers or servers. It consists of a shielded copper cable with pluggable transceivers permanently attached to both ends. These cables operate over “twinax” copper, providing a point-to-point link. Unlike optical transceivers, they do not require separate fiber patches. This integrated design significantly reduces the number of potential failure points in your network.

The primary advantage of a direct attach cable is its extremely low power consumption. Because the signal remains electrical throughout the link, no optical conversion is necessary. This saves approximately 0.5W to 1W per port compared to optical alternatives. For a data center with thousands of ports, this leads to substantial energy savings. Furthermore, copper DACs offer the lowest latency for short-distance transmissions within a rack.

B2B users prioritize DACs for high-speed interconnects due to their cost efficiency. The price of a single copper assembly is much lower than two transceivers plus fiber. This makes it the standard choice for “Top-of-Rack” (ToR) switching architectures. If your connection distance is under 7 meters, a copper DAC is typically the most logical technical decision.

Comparing SFP+ and 25G Direct Attach Cable Performance

Selecting between an sfp+ direct attach cable and a 25G direct attach cable depends on your bandwidth roadmap. The sfp+ direct attach cable is the industry standard for 10Gbps Ethernet. It is widely used for connecting servers to 10G switches in legacy and mid-tier enterprise environments. These cables are highly reliable and offer plug-and-play simplicity across diverse hardware brands.

As data demands increase, the 25G direct attach cable has become the new baseline for cloud providers. It utilizes SFP28 form factors to provide 2.5 times the bandwidth of 10G. Remarkably, 25G DACs maintain similar power profiles to their 10G predecessors. This allows for a massive increase in throughput without requiring a complete overhaul of rack cooling. The SFP28 interface is also backward compatible with SFP+ ports in many switch configurations.

When evaluating these options, consider the “Active” vs. “Passive” distinction. Passive direct attach cables do not contain signal amplification electronics. They are limited to shorter distances, usually up to 5 meters for 10G and 3 meters for 25G. Active DACs include signal processing to extend the reach up to 10 meters or more. For most intra-rack connections, passive cables are preferred due to lower cost and higher reliability.

Strategic Benefits of Direct Attach Cables Wholesale

Purchasing direct attach cables wholesale offers significant advantages for large-scale infrastructure projects. Bulk procurement allows for standardized testing across your entire deployment. This ensures that every direct attach cable meets the same signal integrity benchmarks. Consistent quality reduces the time spent troubleshooting intermittent link flaps during initial setup.

Procuring direct attach cables wholesale also simplifies inventory management. Having a uniform stock of 1m, 3m, and 5m cables prevents project delays. You can ensure that your team always has the correct length for efficient cable management. Clean cabling improves airflow within the rack, which extends the life of your hardware. Bulk buying also provides the leverage to request custom labeling or specific compatibility coding.

From a financial perspective, wholesale sourcing dramatically lowers the “per-port” cost of networking. These savings can then be reallocated to high-value components like core switches or NVMe storage. For B2B buyers, the key is finding a supplier that provides verified EEPROM coding. This ensures the cables are recognized by major switch vendors like Cisco, Arista, or Juniper.

Key Considerations for Network Compatibility

Compatibility remains the biggest hurdle when deploying a direct attach cable in a multi-vendor environment. Many switch manufacturers implement “vendor locking” via the transceiver’s EEPROM chip. If the cable is not properly coded, the switch may disable the port or trigger an alarm. You must verify that your supplier can provide multi-code support for complex setups.

The gauge of the copper wire, known as AWG (American Wire Gauge), also impacts performance. A thicker wire (lower AWG number) can support longer distances with less signal degradation. However, thicker cables are stiffer and harder to route through tight spaces. Balancing flexibility and signal reach is essential for maintaining an organized and functional data center.

Finally, always check the environmental ratings of your cables. High-quality direct attach cables should feature robust strain relief at the connector junction. They should also meet standard flammability requirements for data center environments. Testing for Return Loss and Insertion Loss is critical for ensuring long-term link stability.

Evaluating Your Hardware Interface Standards

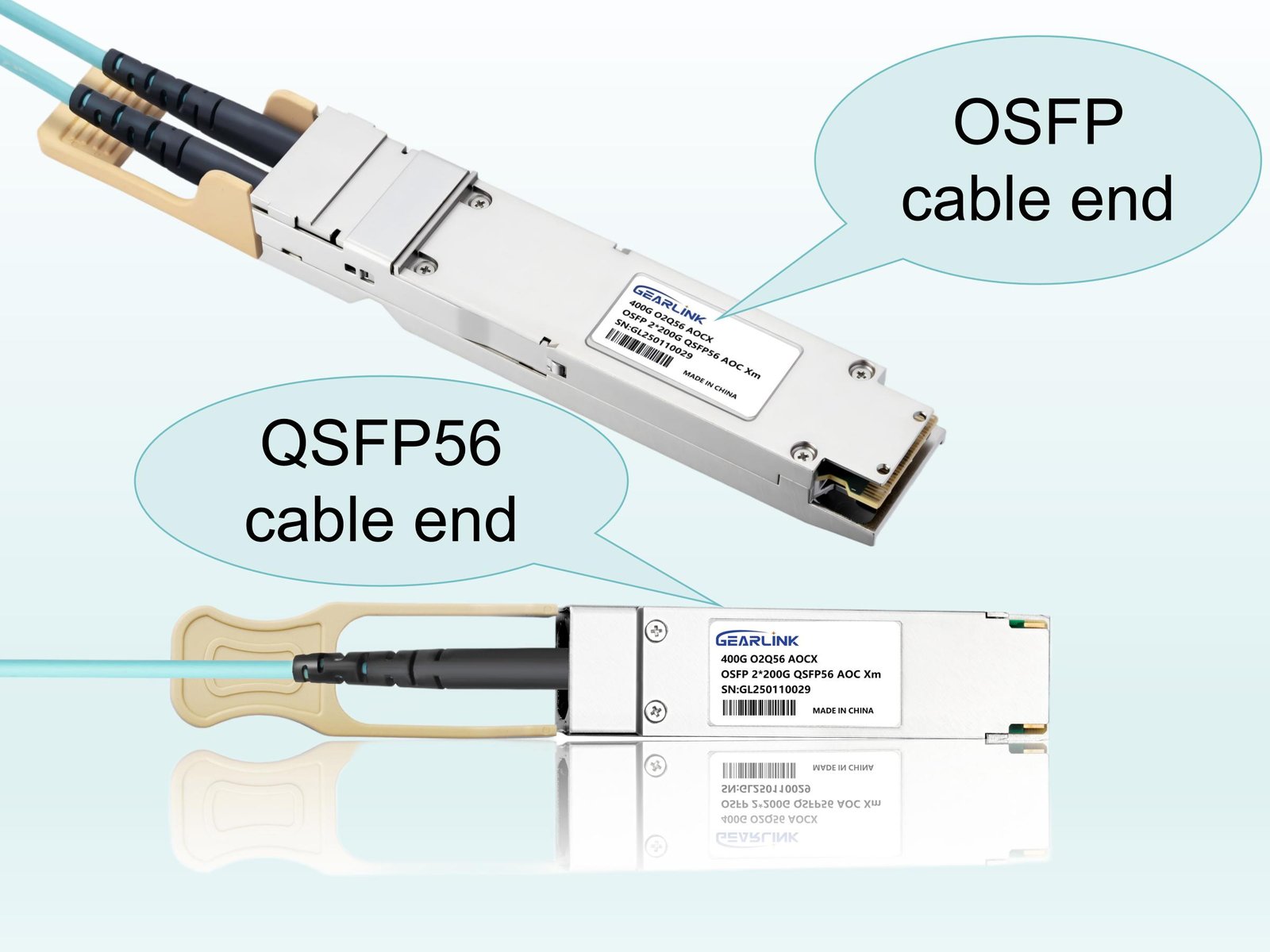

Determining the right interconnect strategy requires a clear understanding of your switch port capabilities. High-density environments often utilize breakout cables to split high-bandwidth ports into multiple slower links. For example, a single 100G QSFP28 port can be converted into four 25G SFP28 links using a breakout direct attach cable. This maximizes the utility of each switch port and reduces the total number of switches required.

To identify the most suitable options for your specific hardware, exploring a comprehensive direct attach cable catalog is a vital step. You should compare the technical specifications of passive versus active assemblies for your required distance. Prioritizing cables that meet MSA (Multi-Source Agreement) standards ensures broad compatibility across your existing and future infrastructure. Selecting a reliable partner for these components will reduce operational risks and improve network uptime.

Summary

Choosing the correct direct attach cable is essential for building a cost-effective and low-latency network. Whether you deploy an sfp+ direct attach cable for 10G or a 25G direct attach cable for modern workloads, focus on compatibility and power efficiency. Sourcing these components via direct attach cables wholesale provides the best balance of quality and value for B2B enterprises.

FAQ

Q1: Can I use a 25G direct attach cable in a 10G SFP+ port? Generally, yes, as SFP28 connectors are physically compatible with SFP+ ports, but the speed will be limited to 10Gbps.

Q2: What is the maximum distance for a passive direct attach cable? Passive copper DACs typically support distances up to 7 meters for 10G, though 3 to 5 meters is recommended for higher speeds like 25G.

Q3: Are direct attach cables compatible with all switch brands? Cables must be specifically coded in the EEPROM to be recognized by certain brands that use vendor-lock features.

Q4: Is a direct attach cable better than an Active Optical Cable (AOC)? DACs are better for very short distances (under 5m) due to lower cost and power use, while AOCs are better for longer reaches and lighter weight.

Reference Sources

SNIA (Storage Networking Industry Association) : Networking Interconnect Dictionary

SFF Committee : SFF-8431 Specifications for SFP+ High Speed Serial Interface