The relentless expansion of cloud computing, Artificial Intelligence (AI), and streaming services has dramatically accelerated the demand for bandwidth, pushing data center networks to adopt 400 Gigabit Ethernet (400G) technology. While 400G optical modules deliver the necessary speed, they simultaneously introduce a critical operational challenge: 400G module power consumption. As data centers strive for energy efficiency and sustainability, the power budget of individual components dictates the viability and scalability of the entire network architecture.

For network architects, equipment manufacturers, and infrastructure planners in the optical module industry, understanding the components that drive this power demand and the emerging technologies designed to mitigate it is essential for strategic decision-making. The key question is: Can the industry successfully continue its trajectory of bandwidth doubling while simultaneously achieving the dramatic reductions in 400G module power consumption required to make hyper-scale data centers truly energy-efficient? This comprehensive guide will dissect the primary factors contributing to the energy draw of 400G modules, explore the technical trade-offs between speed and efficiency, and examine the cutting-edge solutions poised to redefine the power landscape for high-speed optical interconnects.

The Technology Drivers Behind 400G Module Power Consumption

To effectively manage the thermal footprint of a 400G link, it is crucial to analyze the specific technological blocks within the module that demand the most electrical energy. These drivers are fundamentally linked to the complexity required to transmit high-speed data across varying distances.

The Role of Digital Signal Processing (DSP) Chips

The single largest contributor to 400G module power consumption in complex modules, particularly those utilizing coherent or advanced modulation schemes like PAM4, is the Digital Signal Processing (DSP) chip. DSPs are necessary to encode and decode the highly complex signals used to squeeze 400G data rates over fewer optical lanes. Unlike older Non-Return-to-Zero (NRZ) signaling, PAM4 uses four voltage levels to transmit two bits per clock cycle, which doubles the bandwidth but also significantly increases signal integrity challenges. The DSP performs crucial equalization, error correction (Forward Error Correction, or FEC), and re-timing functions to clean up these complex, noisy signals. The computational intensity required for these algorithms directly translates into high power usage. Therefore, advancements in silicon photonics and process nodes (e.g., migrating from 7nm to 5nm or 3nm) are primary levers used by manufacturers to reduce the inherent power draw of the DSP.

Opto-Electronics and Laser Efficiency

While the DSP is the dominant electrical consumer, the opto-electronic components, including the laser drivers, modulators, and receivers, also contribute significantly to the total 400G module power consumption. High-speed data transmission requires powerful laser drivers to modulate the light source accurately and rapidly. The efficiency of the laser source itself, typically a Distributed Feedback (DFB) or Electro-absorption Modulated Laser (EML), affects the overall power budget. Less efficient lasers require more power to produce the necessary optical output power. Furthermore, the Thermal Electric Cooler (TEC), often employed in higher-power lasers and components to maintain optimal operating temperature and ensure wavelength stability, represents a parasitic power draw. Consequently, the industry is increasingly favoring solutions that eliminate the need for a TEC, such as uncooled optics, wherever feasible, especially in short-reach applications like those inside the data center.

Thermal Management: The Key Challenge Driven by 400G Module Power Consumption

The high power consumption of 400G modules presents an immediate and substantial thermal challenge for networking hardware. Efficiently dissipating this heat is critical for reliability and maximizing port density.

The Impact on Data Center Infrastructure

The concentrated heat generated by a rack full of 400G modules directly impacts the data center’s cooling infrastructure. Every additional Watt consumed by the module must be actively removed by the facility’s cooling system, which itself consumes significant electrical power. This relationship, known as the Power Usage Effectiveness (PUE) multiplier, means that reducing 400G module power consumption offers a cascading benefit: lower energy costs for the network equipment and lower energy costs for cooling. Moreover, excessive heat dramatically accelerates component degradation, reducing the lifespan of the transceivers and surrounding switch gear. Therefore, effective thermal management is not just a performance issue; it is an economic and reliability imperative.

Module Form Factors and Heat Dissipation

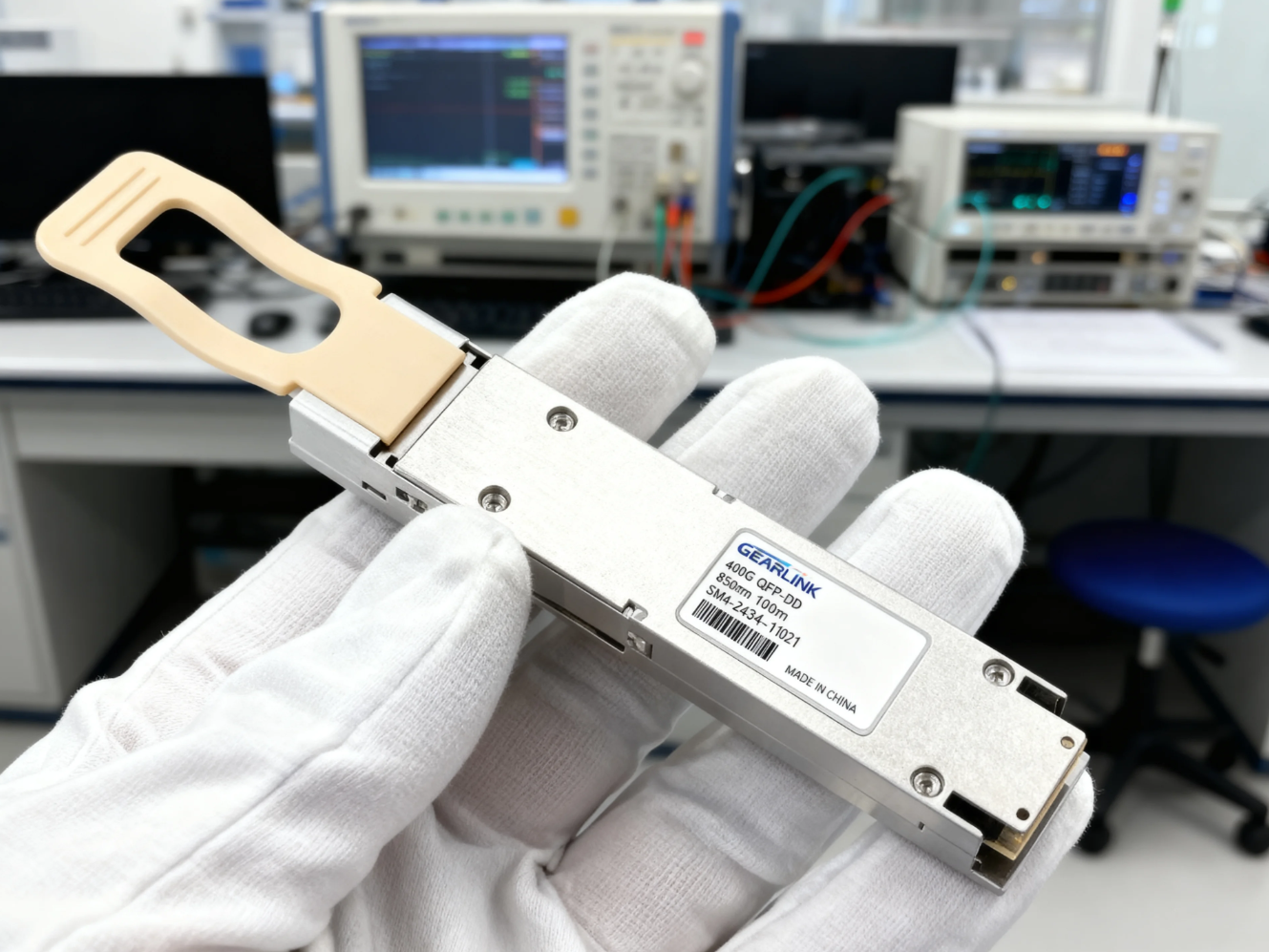

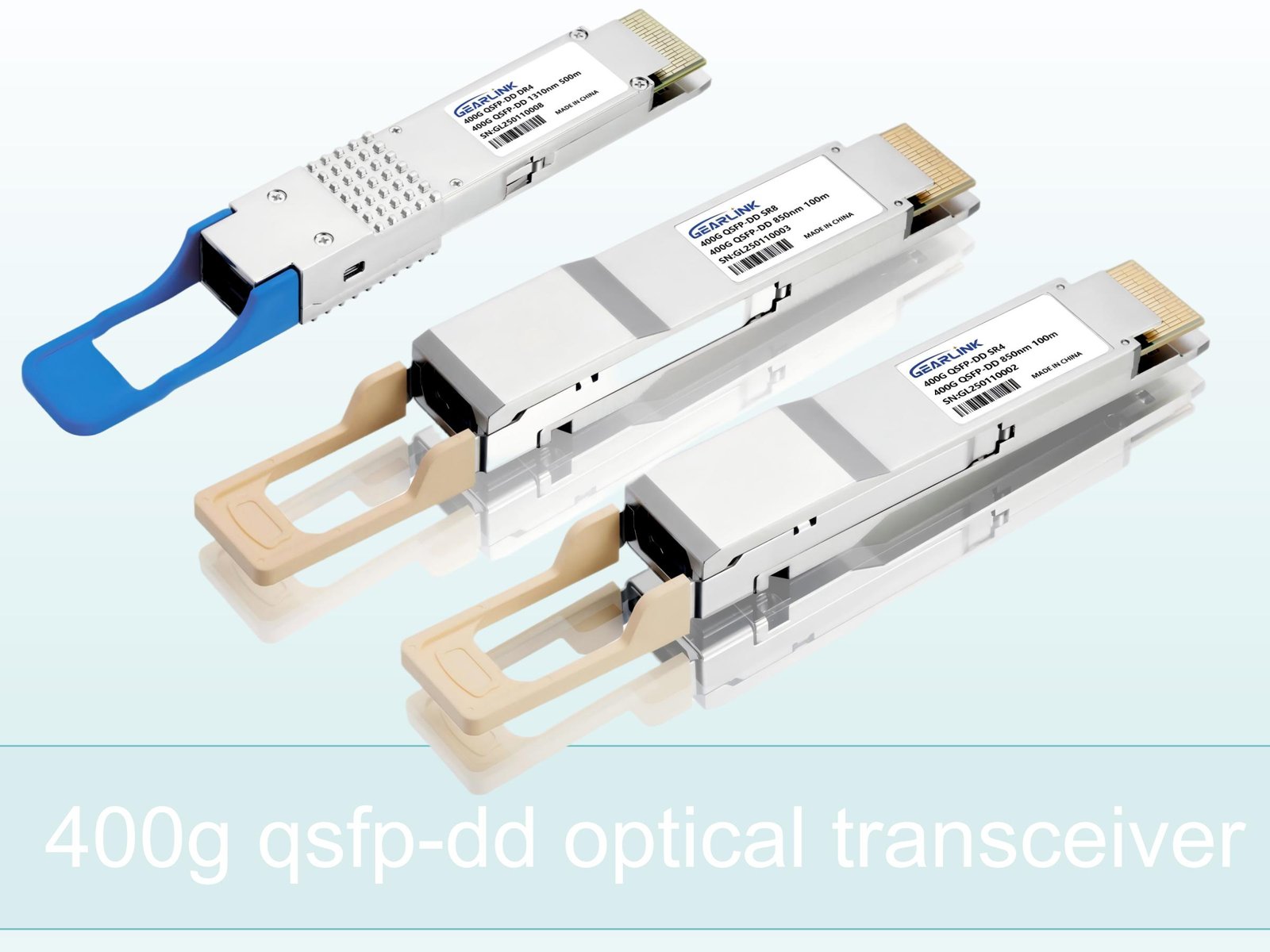

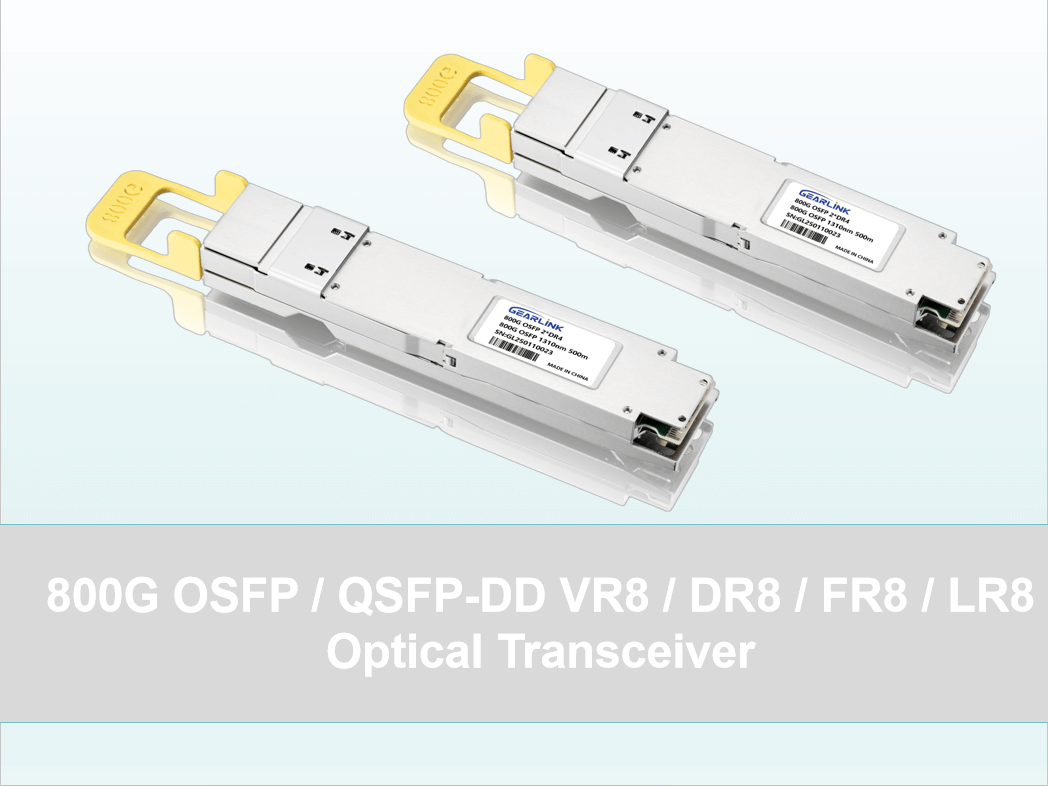

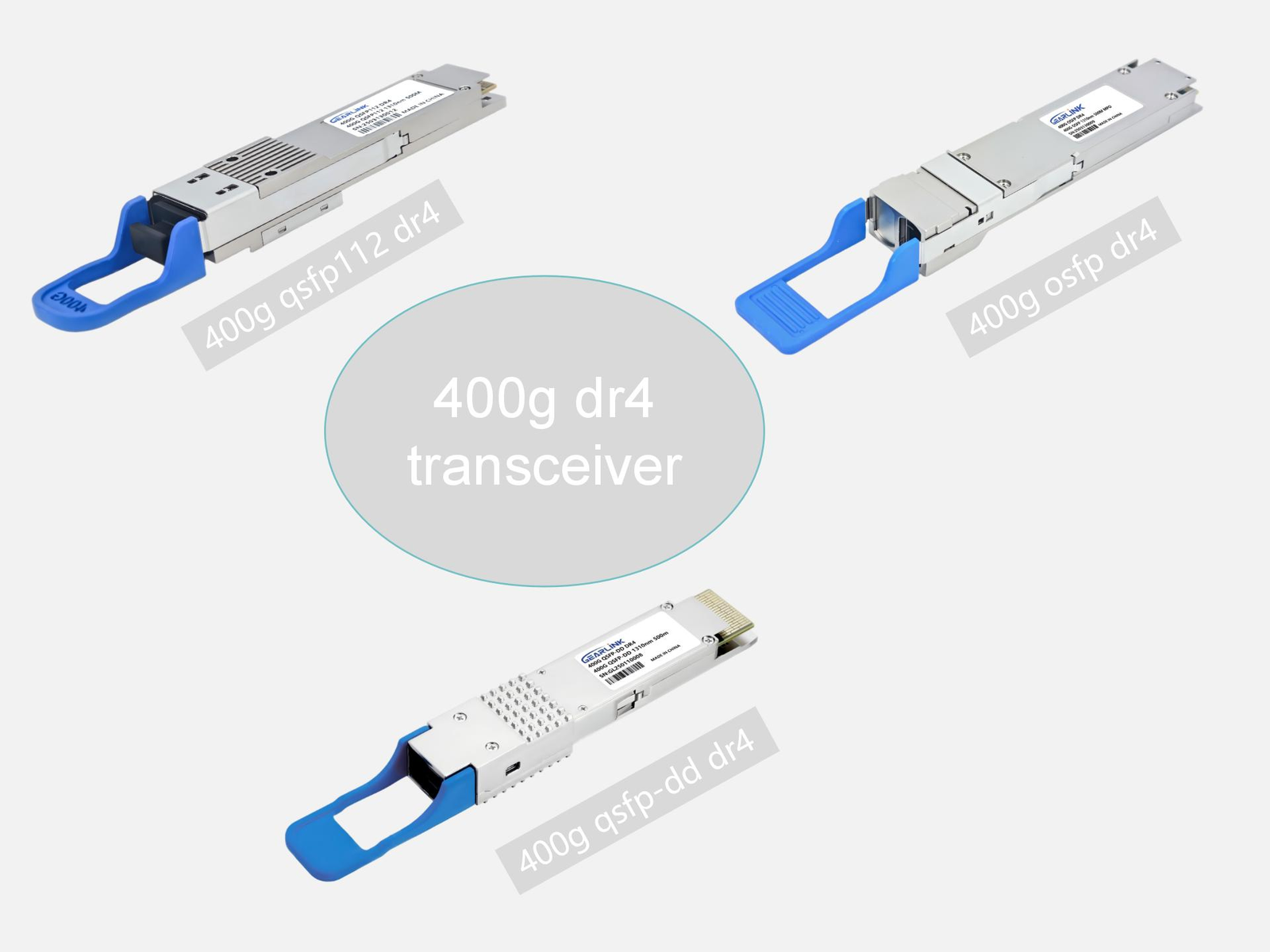

The design of the 400G module form factor (e.g., QSFP-DD, OSFP) is engineered to maximize heat transfer away from the internal components. Both QSFP-DD and OSFP were specifically developed to handle higher power loads than previous generations. They feature larger surface areas and advanced thermal interfaces designed to channel heat to the host switch’s heat sink and chassis. However, simply relying on passive heat dissipation becomes insufficient as power levels approach 15-20 Watts per module. Manufacturers continuously innovate in thermal interface materials (TIMs) and heat sink designs to optimize the heat path. The success of any high-power 400G implementation relies on the host system’s ability to efficiently cool these dense form factors.

Strategic Optimization: Reducing 400G Module Power Consumption

400GBASE-SR4 OSFP 850nm 50m DOM MPO-12/APC MMF Optical Transceiver Module

Price range: NT$499 through NT$898

The future of high-speed optical networking depends on decoupling bandwidth growth from power growth. Industry efforts focus on several key areas to achieve this critical power efficiency.

Co-Packaged Optics (CPO) and Near-Packaged Optics (NPO)

One of the most revolutionary approaches to mitigating 400G module power consumption is the move toward Co-Packaged Optics (CPO). CPO integrates the optical components and the electrical switch ASIC onto the same substrate within a single package, drastically reducing the distance electrical signals must travel. This shortens the copper trace length, which lowers electrical signaling loss and allows the use of lower-power DSPs or even eliminates the need for complex equalization, leading to substantial power savings (potentially 30% or more). Near-Packaged Optics (NPO) offers a transitional step, placing the optics very close to the ASIC. While CPO represents a fundamental shift in switch design, its adoption is essential for achieving ultra-low power consumption goals in next-generation networks.

Leveraging Silicon Photonics and Integration

Silicon Photonics (SiPh) technology is central to achieving low power and high volume at a reasonable cost. By fabricating passive and active optical components using high-volume CMOS manufacturing processes, SiPh allows for the integration of multiple functions onto a single chip. This high level of integration minimizes the number of discrete components and electrical interconnects, reducing signal loss and parasitic capacitance, which in turn lowers the overall 400G module power consumption. As SiPh processes mature, the integration of even the laser sources and the DSP logic onto the same platform offers a pathway to unprecedented levels of energy efficiency in optical modules.

Software Defined Control and Low Power Modes

Beyond hardware advancements, software control plays an increasing role in optimizing 400G module power consumption. Modern modules support various operational modes that allow the network administrator to dynamically adjust power usage based on traffic load. For example, some modules can operate in a low-power standby state during periods of low traffic, or their internal components can be configured for power-optimized settings versus full-speed performance settings. Leveraging these Software Defined Networking (SDN) capabilities allows data centers to manage their energy footprint more intelligently and achieve significant power savings on a network-wide scale without sacrificing peak performance capacity when it is needed.

Frequently Asked Questions (FAQ)

Q1: What is the main reason 400G module power consumption is higher than 100G modules?

A: The primary reason is the reliance on complex signaling and error correction, mainly through PAM4 modulation and the sophisticated Digital Signal Processing (DSP) chips required to manage the increased signal noise and achieve the higher data rate (400G vs 100G) using a similar number of optical lanes.

Q2: How does the industry plan to lower 400G module power consumption in the near future?

A: The main strategies include migrating to smaller geometry semiconductor process nodes (e.g., 5nm or 3nm) for DSPs, improving laser efficiency, adopting uncooled optics where possible, and, strategically, exploring Co-Packaged Optics (CPO) which reduces electrical trace length and associated power loss.

Q3: Does the form factor (QSFP-DD or OSFP) affect the heat management challenge?

A: Yes. Both QSFP-DD and OSFP were designed to handle higher heat than predecessors, but their physical size and thermal interface properties differ. OSFP is slightly larger, which potentially gives it a minor advantage in raw heat dissipation capability, though both are engineered to manage the high thermal loads associated with high 400G module power consumption.