In the rapidly evolving landscape of high-performance computing, the need for increased bandwidth and port density is perpetually escalating. This relentless demand, driven primarily by hyperscale cloud services, Artificial Intelligence (AI) operations, and massive data storage requirements, places immense pressure on the underlying optical interconnect infrastructure. Central to this infrastructure transformation is the 400G QSFP-DD SR8 optical module, a marvel of miniaturization and engineering efficiency. The specialized 400G QSFP-DD SR8 factory where these sophisticated components are meticulously assembled, tested, and prepared for deployment is not merely a production site; it serves as the crucial manufacturing backbone enabling the next generation of data center architecture. Understanding the processes, features, and stringent quality control inherent to the production of this module provides tangible value to optical product users seeking reliability and performance at scale. This in-depth analysis will explore the profound impact of this technology and the detailed manufacturing processes that bring it to life, focusing on its specific applications within the realm of optical networking.

The Technological Genesis: Decoding the 400G QSFP-DD SR8 Module

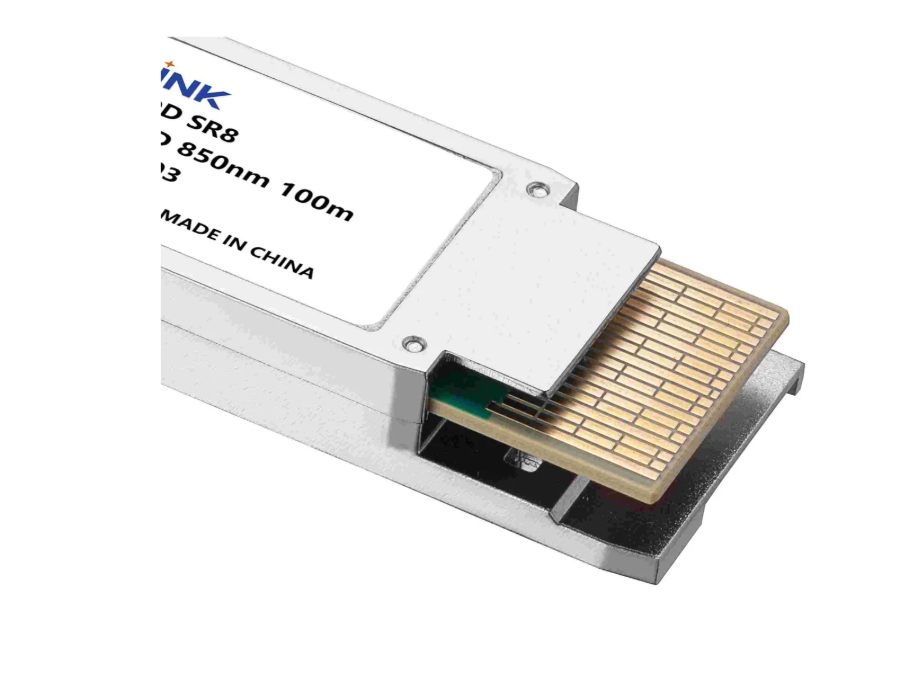

The 400G QSFP-DD SR8 module represents a significant leap from previous generations, primarily utilizing the Quad Small Form-factor Pluggable Double Density (QSFP-DD) form factor. This design innovation effectively doubles the number of high-speed electrical lanes from four to eight, thus supporting 400 Gbps total throughput while maintaining backward compatibility with existing QSFP modules. This dual density capability is a game-changer for data center operators grappling with rack space limitations, allowing for a considerable increase in front-panel port density.

The “SR8” designation is equally crucial, signifying “Short Reach, 8 channels.” This specifies that the module operates over eight optical channels, each running at 50 Gbps using Pulse Amplitude Modulation (PAM4) signaling, for short-haul transmission over Multi-Mode Fiber (MMF). Typically, it is designed for links up to 100 meters, making it the ideal choice for high-density, intra-rack, or adjacent-rack connections within massive data center fabrics. Furthermore, the SR8 configuration inherently facilitates breakout applications, where the single 400G link can be logically separated into two 200G links or four 100G links, offering exceptional flexibility in network deployment and simplifying the migration path from 100G and 200G networks. Consequently, the meticulous manufacturing standards upheld by the 400G QSFP-DD SR8 factory directly translate into the operational efficiency and long-term stability of the interconnected systems.

A Deeper Look into the Factory Floor: Precision Manufacturing for Optical Excellence

The production of high-speed optical modules like the 400G QSFP-DD SR8 is an inherently complex, multi-stage process that requires extreme precision and a sterile environment—conditions that are consistently maintained in a specialized 400G QSFP-DD SR8 factory.

Automated Assembly and Photonic Integration

The journey begins with the fabrication of the core components: the high-speed laser drivers, the Receiver Optical Sub-Assemblies (ROSAs), and the Transmitter Optical Sub-Assemblies (TOSAs). These components utilize advanced materials, including Vertical-Cavity Surface-Emitting Lasers (VCSELs), which are central to the SR8’s multi-mode operation. Unlike simpler electronics, the physical alignment of the light source, the fiber interface, and the photodetectors must be accurate to within sub-micron tolerances. Automated precision machinery, often utilizing robotic arms and machine vision, is indispensable in the 400G QSFP-DD SR8 factory to perform the active alignment and bonding of the TOSA/ROSA elements to the silicon planar lightwave circuits (PLCs). This level of automation is essential not only for achieving the required optical performance but also for ensuring cost-effective, high-volume production.

Rigorous Testing and Quality Assurance Protocols

Manufacturing errors in an optical module can result in unacceptable levels of signal degradation, which translates to massive packet loss in a data center environment. Therefore, the testing and quality assurance stages within the 400G QSFP-DD SR8 factory are arguably the most critical. Each module undergoes a comprehensive suite of tests before being shipped. This includes:

- Electro-Optical Performance Testing: This verifies the module’s sensitivity, transmit power levels, and eye-diagram quality against the rigorous IEEE 802.3bs standards. The PAM4 signaling integrity is meticulously checked to ensure minimal jitter and noise.

- Environmental Stress Testing: Modules are subjected to thermal cycling and humidity tests to simulate the harsh, fluctuating environmental conditions often found in real-world data centers. This step guarantees long-term operational resilience.

- Interoperability Testing: Critical for the end-user, this involves checking the module’s compatibility with a diverse range of host-side equipment, including different switches and routers, across multiple vendors.

Through these stringent controls, the 400G QSFP-DD SR8 factory provides the assurance that the modules will perform reliably for the thousands of hours they are expected to operate in a high-demand network setting.

The Value Proposition in Optical Networking Applications

For users in the optical networking space, particularly those designing and maintaining hyperscale data centers, the adoption of the 400G QSFP-DD SR8 module offers compelling advantages that directly address operational bottlenecks.

Maximizing Density and Minimizing Cost

The compact QSFP-DD form factor allows data center operators to achieve an unprecedented level of port density, maximizing the throughput per unit of rack space. By supporting 32 ports of 400G in a single 1U switch, for example, the total switching capacity can reach 12.8 Tbps. Moreover, the decision to use the SR8 variant, which relies on the widely available and cost-effective multi-mode fiber infrastructure, often results in significant savings in overall fiber plant costs compared to longer-reach single-mode solutions. The ability of the 400G QSFP-DD SR8 factory to mass-produce these modules efficiently further drives down the cost per bit, which is the ultimate metric of performance for large-scale network deployments.

Enabling the Spine-Leaf Architecture Evolution

Modern data centers are universally built upon the spine-leaf topology, which requires high-speed, low-latency links between the leaf (access) and spine (aggregation) layers. The 400G QSFP-DD SR8 module is ideally positioned to upgrade these critical interconnections. Its short-reach capability is perfect for linking leaf switches to spine switches within the same row or adjacent racks, providing the high-bandwidth paths necessary to handle massive East-West traffic flows. This module thus becomes an essential building block for constructing non-blocking, scalable network fabrics that are required to support AI training clusters and other bandwidth-intensive applications. Therefore, the consistent output and quality control from the 400G QSFP-DD SR8 factory are paramount to the successful deployment of these next-generation fabric upgrades.

Future Perspectives: Sustaining Innovation and Scaling Production

Looking ahead, the optical module manufacturing sector faces the twin challenges of sustaining innovation while continually scaling production to meet global demand. The current industry trend is already shifting towards the 800G generation, utilizing the QSFP-DD800 standard. Nevertheless, the 400G QSFP-DD SR8 factory remains vital, providing the fundamental, proven technology that underpins the vast majority of current cloud data center expansion projects.

Furthermore, the manufacturing process is increasingly incorporating advanced techniques such as silicon photonics and co-packaged optics (CPO) to further improve power efficiency and integration density. Manufacturers are focused on reducing power consumption per gigabit—a crucial operational expenditure for massive data centers. Through ongoing research and development, coupled with continuous process refinement on the factory floor, the specialized 400G QSFP-DD SR8 factory ensures its products are not only compliant with today’s standards but are also designed with an eye toward future scalability, cementing the module’s role as a cornerstone of high-speed optical networking for years to come. Ultimately, the quality and innovation originating from these manufacturing sites directly empower users to build the robust, high-performance digital infrastructure the world now depends upon.

FAQ

Q1: What are the primary applications of the 400G QSFP-DD SR8 module? A1: The module is primarily used for short-reach, high-density interconnections within hyperscale and enterprise data centers. Its main applications include intra-rack and adjacent-rack links, connecting leaf and spine switches in a fabric architecture, and facilitating high-speed links for AI/ML compute clusters.

Q2: How does the “DD” (Double Density) feature benefit data center operators? A2: The Double Density feature is a mechanical and electrical standard that allows the module to house twice the number of high-speed electrical lanes (8 lanes) compared to the standard QSFP form factor. This critically doubles the total bandwidth (from 200G to 400G) while maintaining the compact module size, thus maximizing port density on the switch faceplate.

Q3: Is the 400G QSFP-DD SR8 module compatible with Single-Mode Fiber (SMF)? A3: No, the SR8 designation specifies Short Reach operation using Vertical-Cavity Surface-Emitting Lasers (VCSELs), which are designed to operate over Multi-Mode Fiber (MMF). For longer-reach 400G applications over SMF, different module types like 400G DR4 or FR4 are utilized.

Q4: What role does the factory play in ensuring the reliability of 400G QSFP-DD SR8 modules? A4: The 400G QSFP-DD SR8 factory implements highly automated, sub-micron precision assembly for TOSA/ROSA components and VCSELs. Crucially, every module undergoes rigorous Electro-Optical Performance Testing and environmental stress testing to guarantee compliance with industry standards and reliable long-term performance under demanding data center conditions.